Open fieldbus systems

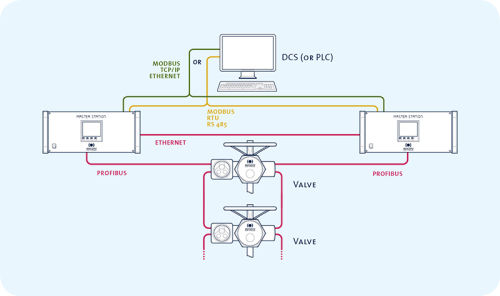

The fieldbus present on a large number of installations is used more and more to communicate information and commands with multiple actuators and contactors connected in series on a single pair of wires.

Easy site management

Thus, the number of information available from each actuator can be multiplied while reducing the overall cost of wiring on the site.

BERNARD CONTROLS actuators can be connected to most of the standard fieldbus available on the market:

- PROFIBUS DP,

- FOUNDATION FIELDBUS,

- MODBUS RTU,

- Other fieldbus on demand.

For more security, redundant fieldbus ensures continuous operation, even in case of a bus line disruption. Indeed, all elements of the bus loop (bus controller, lines, actuators interfaces) are doubled.

Open versus Proprietary systems:

The « Proprietary » so-called system:

This is a technology designed by a device manufacturer for his own needs. A «Proprietary» system always includes the actuators with the specific bus interface, but also the bus controller located at the line head-end. Only the products proposed by the bus controller manufacturer can be installed on the bus.

« Open » systems:

One using standard international fieldbuses so various manufacturers can supply compatible controllers and interfaces. The actuator supplier restricts usually its offer to devices equipped with bus interfaces. The bus controller is usually included in the PLC.

BERNARD CONTROLS chooses the «open» system for all its fieldbus solutions.

In addition, for increased user-friendliness, Bernard Controls has developed the Master Station, a turn-key solution which eases the command and control of large quantities of MOVs through a fieldbus.

This system allows not only setting up, commanding and getting information from the actuators easily and rapidly but it is also a tool for effective and preventative maintenance.

The Master Station is an intuitive interface equipped with a color touch screen and able to interface with a monitoring computer (optional) to control directly valves'automation.

This PC workstation, equipped with specific software, allows to operate the MOVs and to retrieve data and alarms from the field units.